60cm Obitsu Knee Joint Replacement

To replace the knee joint the first thing you will need to do is remove both halves of the broken joint part.

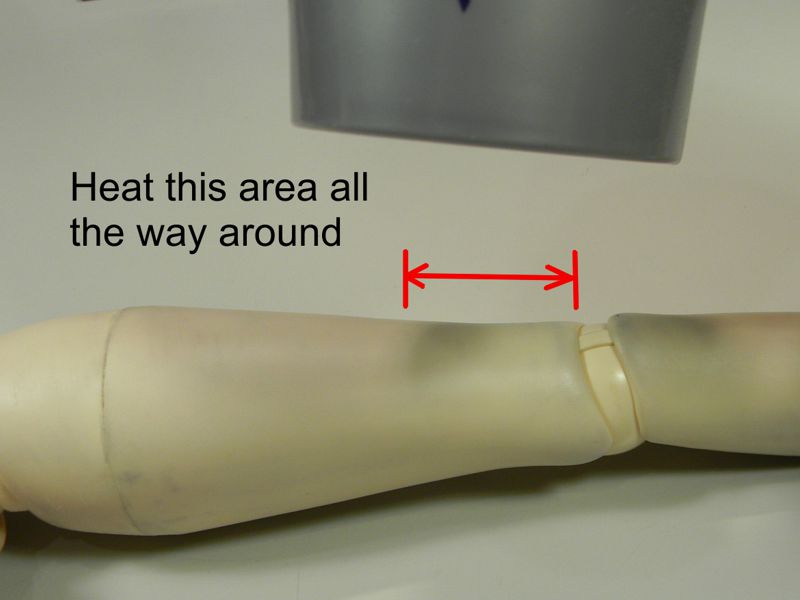

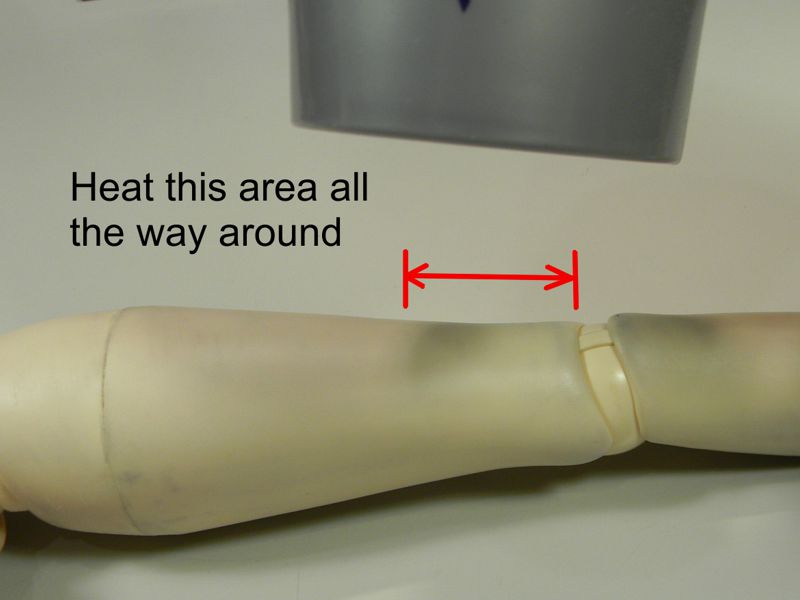

Take your hair dryer and heat the area just above the knee.

Depending on the wattage of your hair dryer heating may take a minute or two. The vinyl should be very soft and squeezable (Be careful, it will be very warm!).

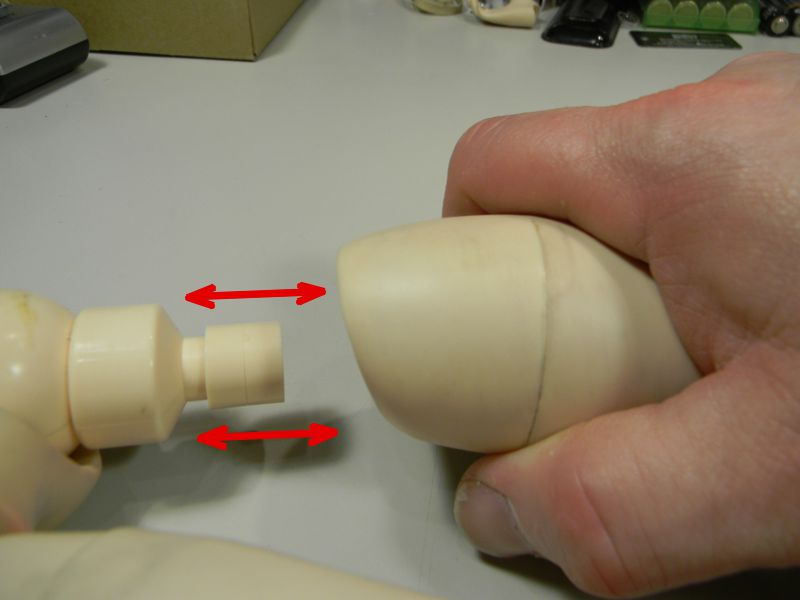

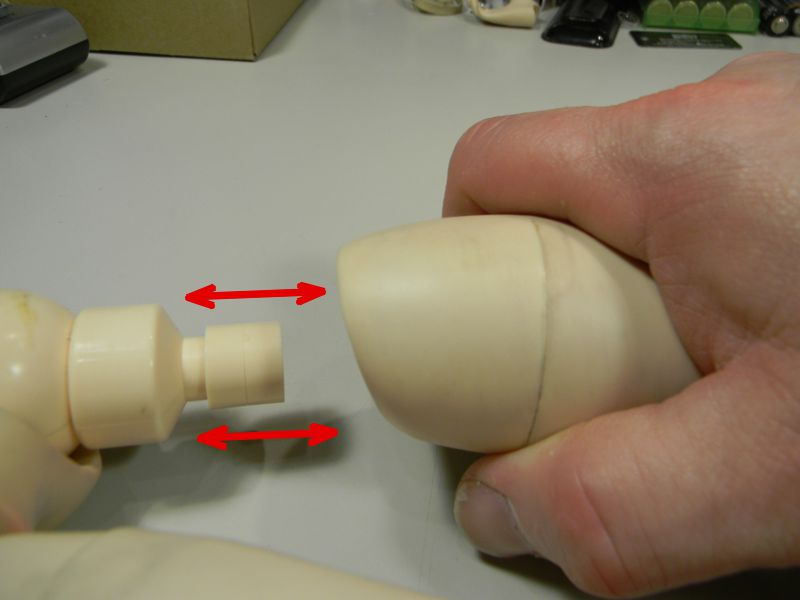

Pull the upper half of the knee joint out of the thigh vinyl. You should be able to pull it out without tools.

If it won’t come out, heat it more. The vinyl will with stand more heating than you think. Just be careful not to touch the dryer to the vinyl to avoid burning it.

Continue the disassembly by pulling the thigh vinyl off of the hip joint. It should just slide off.

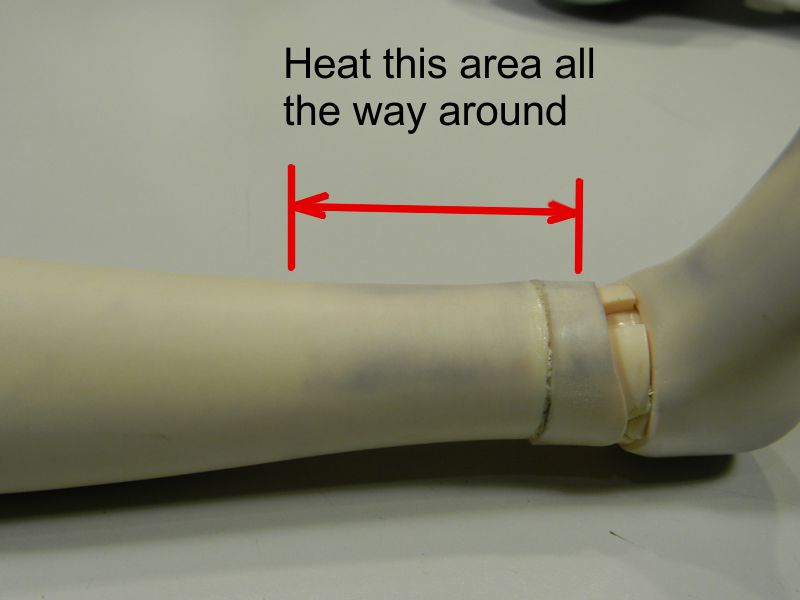

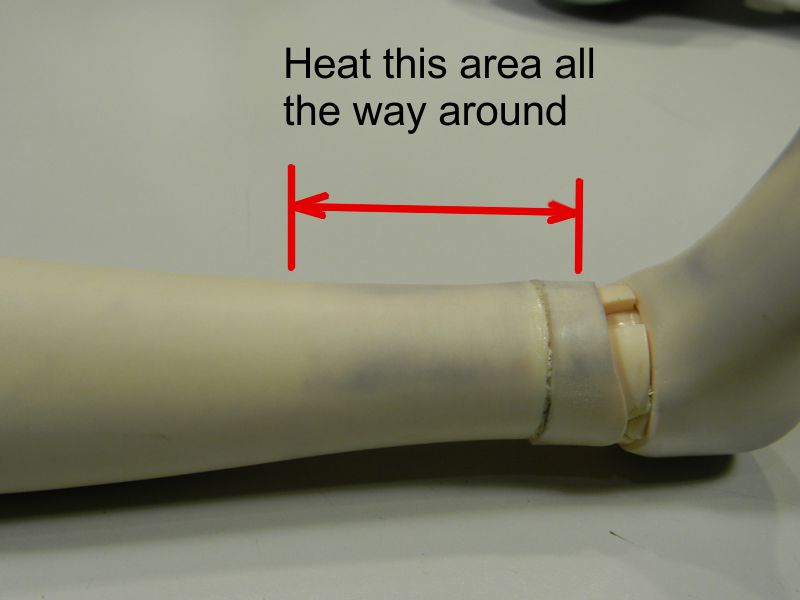

To remove the lower part of the broken knee joint, heat the shin just above the ankle.

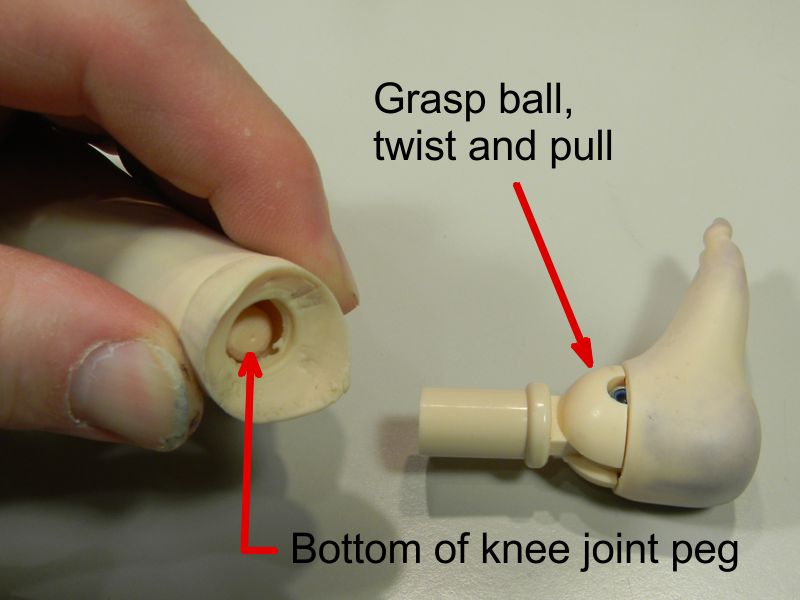

Grasp the ball part of the ankle joint and pull the entire foot and ankle off. Again, heat, heat, heat!

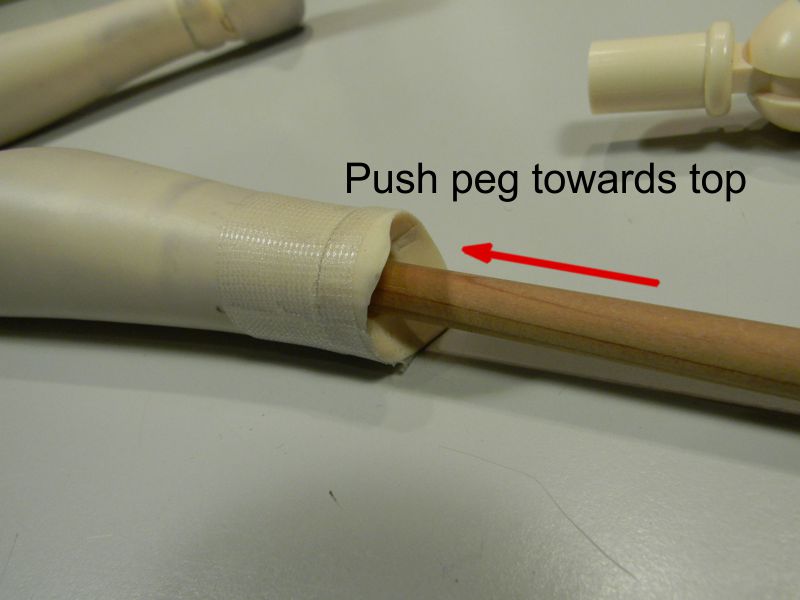

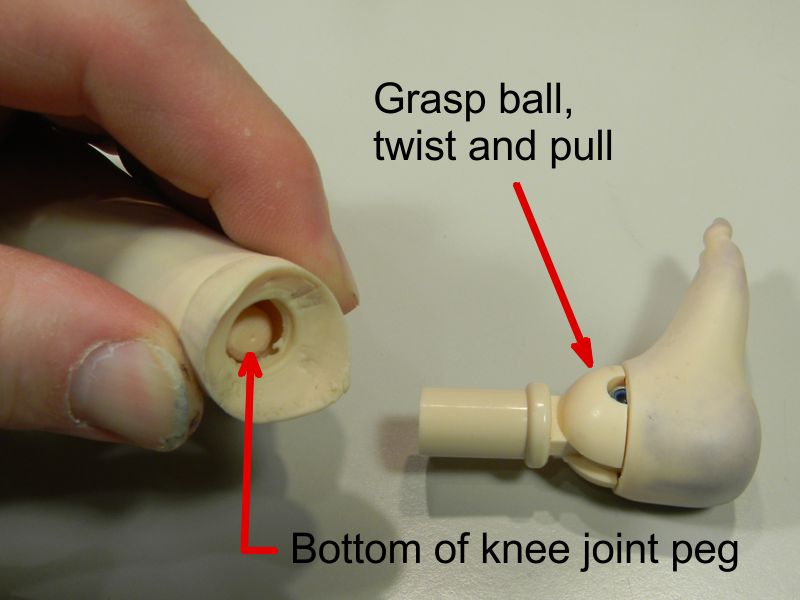

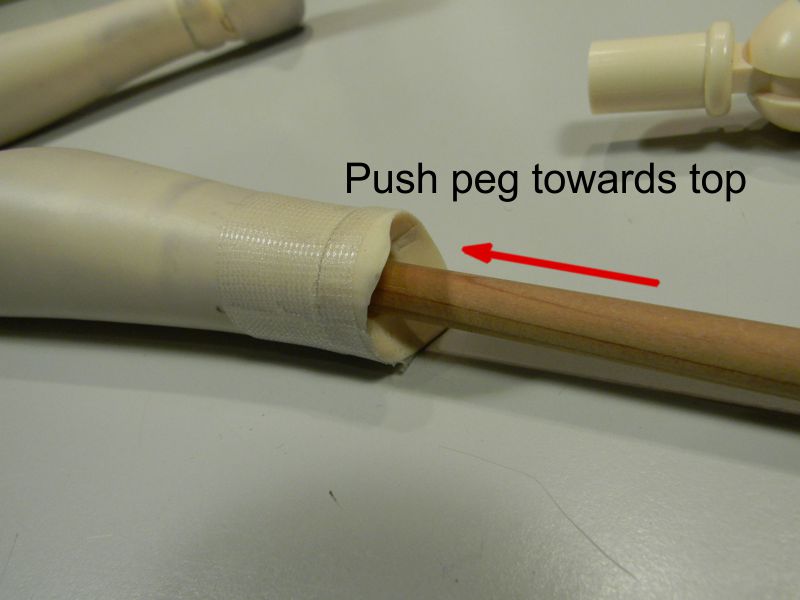

With the foot off, use an unsharpened pencil or dowel rod or some other blunt object and push the lower knee joint peg up and out of the top of the shin.

If the peg doesn’t push out easily you may need to heat the top of the shin vinyl.

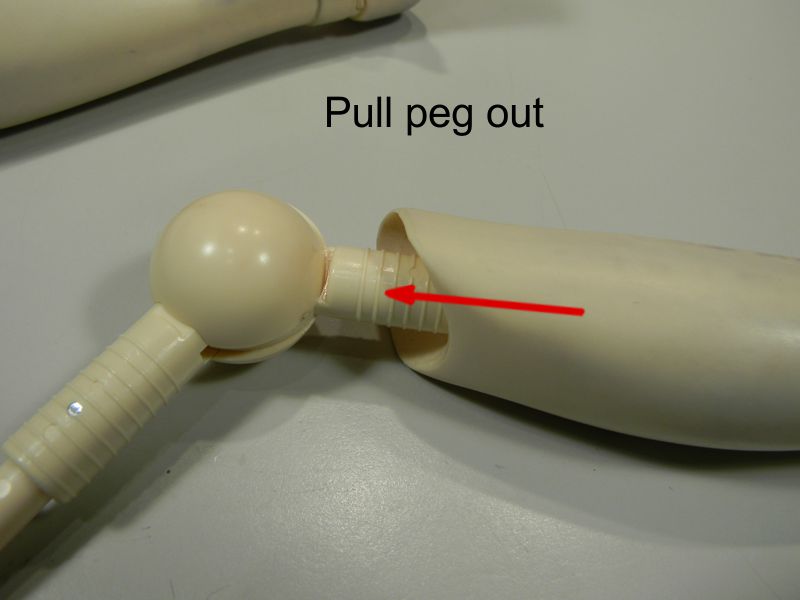

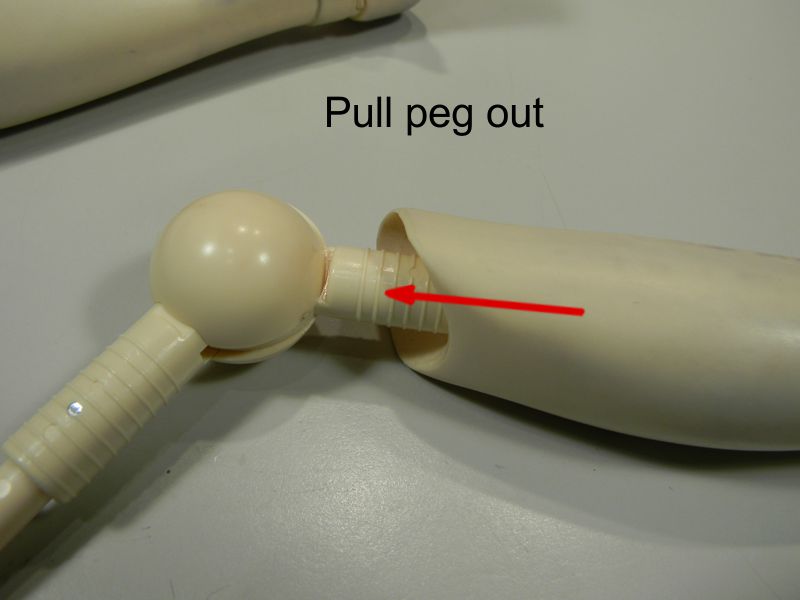

As you can see, the ends of the pegs next to the ball part of the joint are ribbed. This ribbing helps hold the skeleton parts in the vinyl but still allows the parts to rotate.

With the joint disassembled, now is the time to adjust the knee joint tension. I don’t recommend adjusting these joints except under extreme circumstances. These joints will seem very stiff, especially compared to elastic jointed resins, but tight joints are a good thing. Tight joints allow these dolls to really hold a pose. So I wouldn’t mess with these.

But now that we’re here, this is what you would do. This is also what you would do to tighten up a loose joint.

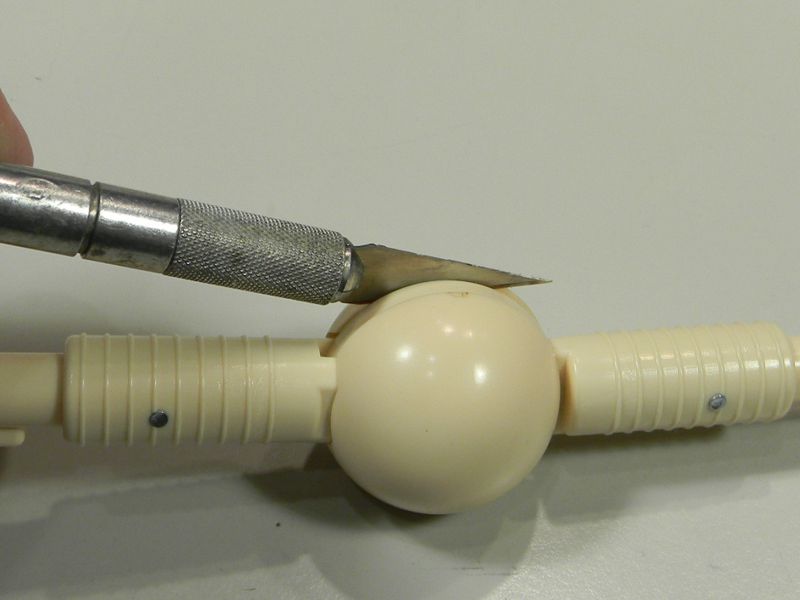

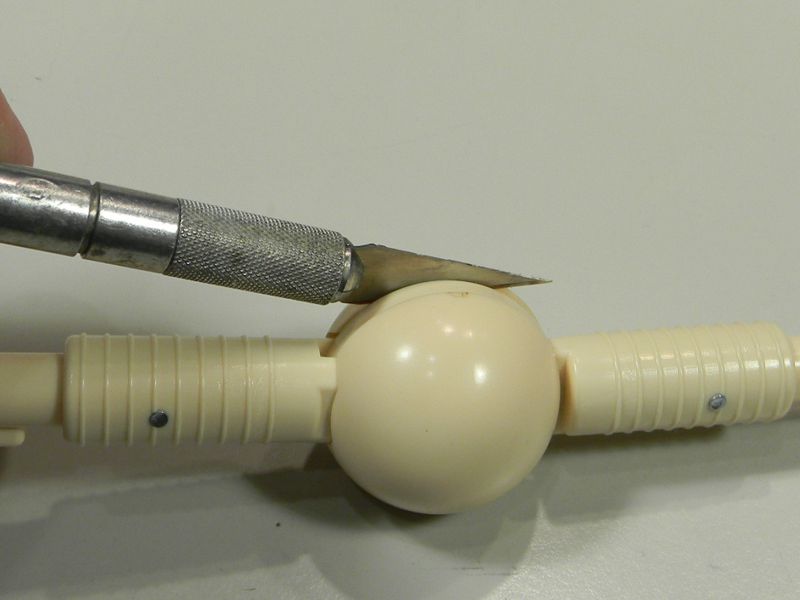

Pop one of the half domes of the ball joint off. This can be done by taking a hobby knife and easing the blade between the dome and the center disk of the joint.

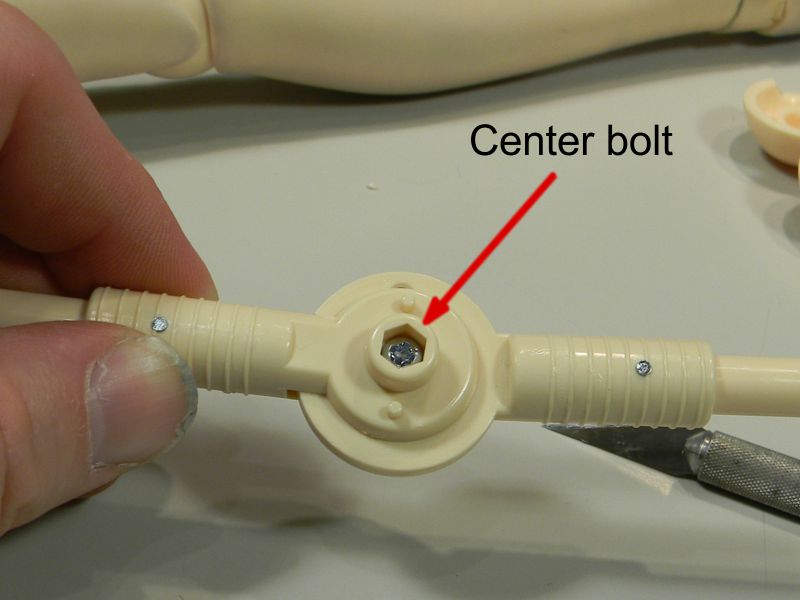

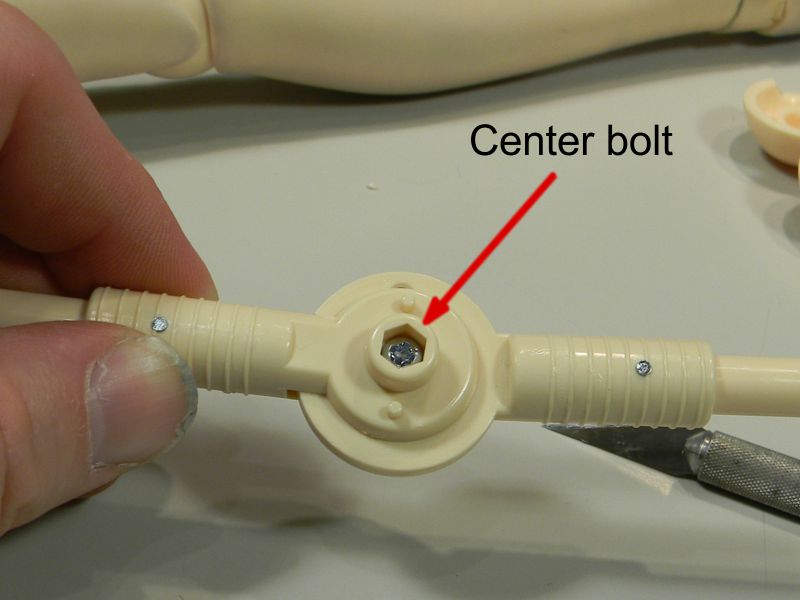

If you’re lucky you’ll see a small Philips bolt head in the center. If you see a hex nut, the bolt head is on the other side so remove the other dome.

With a small Philips screw driver tighten or loosen the bolt head as needed, depending on if you’re tightening or loosening the joint. Replace the domes before installing the joint. The domes are the same on both sides and will just snap right in with the “slot” in the edge going towards the thigh.

Now you’re ready to place the new knee joint in the leg. First we’ll assemble the upper part of the leg.

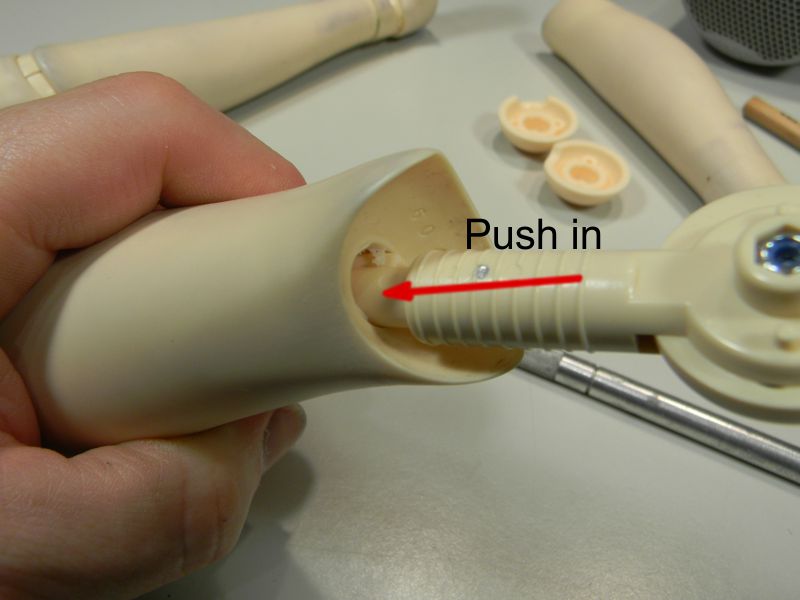

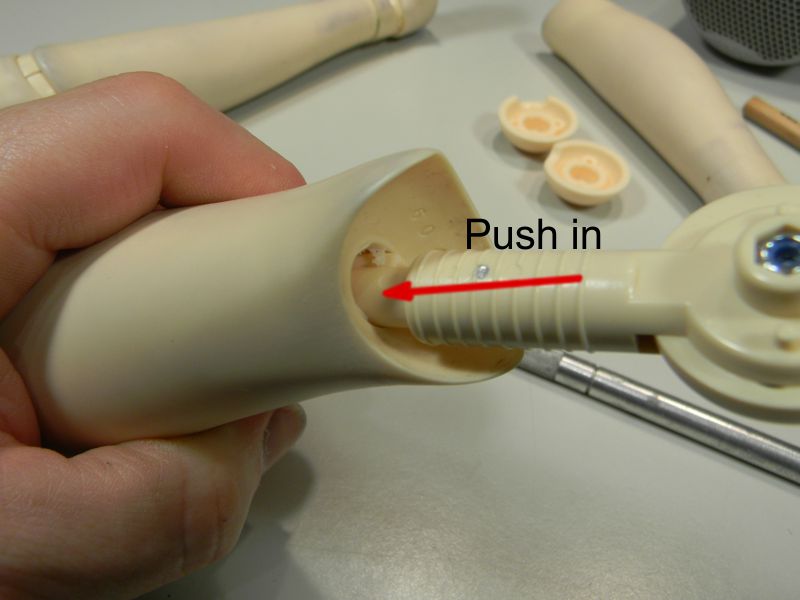

Insert the upper peg into the bottom of the thigh vinyl. If you can’t push it in, heat the vinyl.

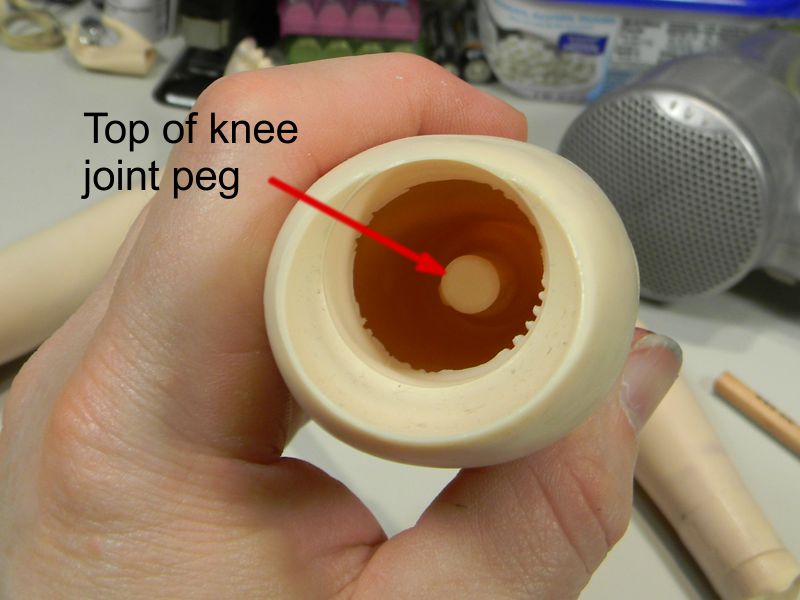

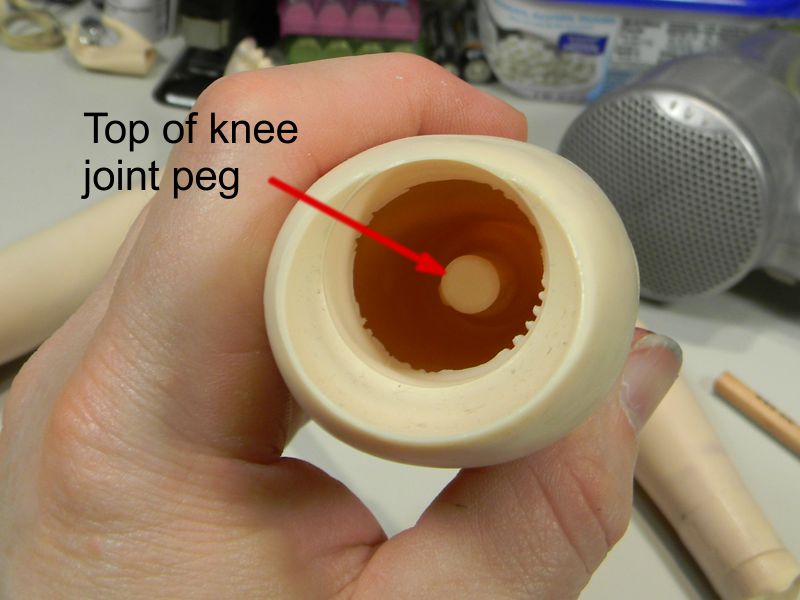

You should see the peg need the top opening of the thigh.

With one hand hold the knee joint and thigh vinyl so the peg is centered in the opening. Now try to inset the hip joint so the peg goes into the hip joint.

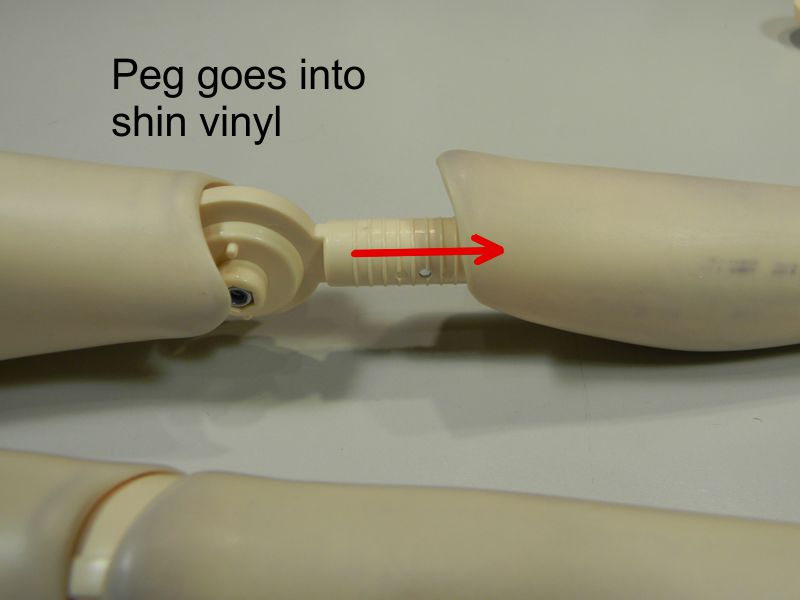

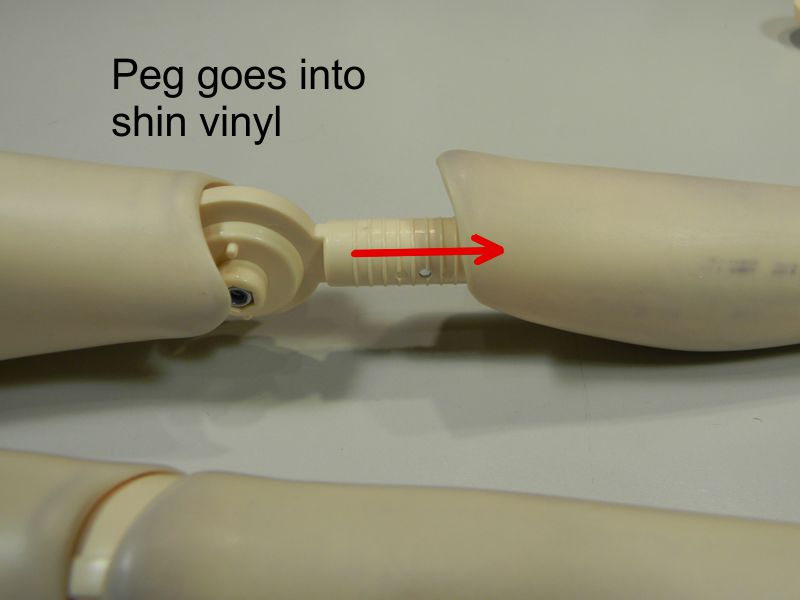

Next slip the bottom peg into the top of the shin vinyl. The two vinyls should fit nice and tight around the ball. If the shin doesn’t push on easily, heat ‘er up.

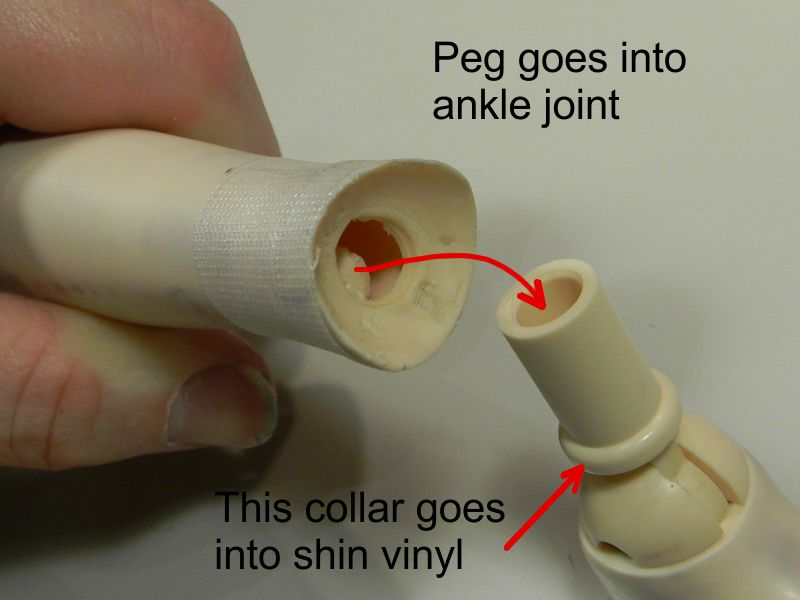

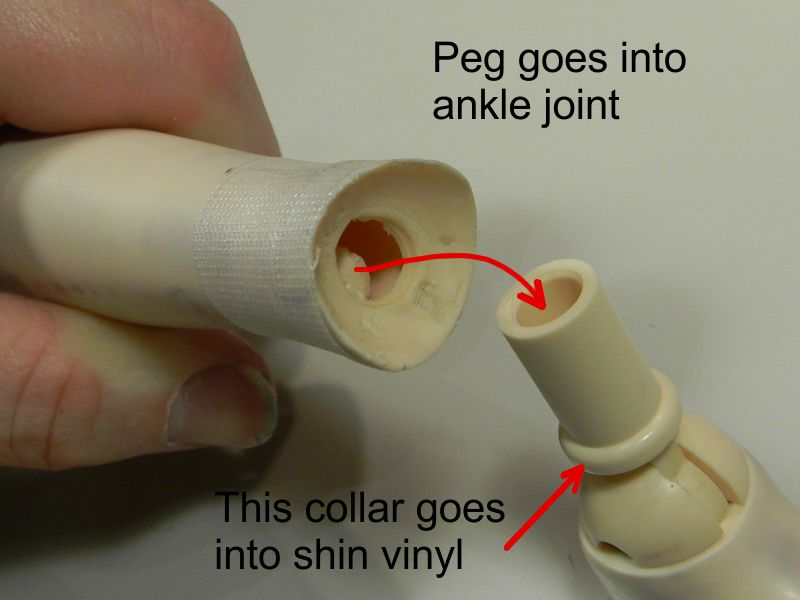

Finally you need to re attach the foot/ankle. Again, heat the bottom of the shin vinyl till it’s soft, then push the top of the ankle into the shin vinyl while trying to engage the peg. Once the peg has started into the ankle joint, push the ankle joint completely into the shin vinyl. The large collar at the bottom of the ankle tube needs to go into the shin vinyl. Heat the vinyl as needed.

That should do it.

Take your hair dryer and heat the area just above the knee.

Depending on the wattage of your hair dryer heating may take a minute or two. The vinyl should be very soft and squeezable (Be careful, it will be very warm!).

Pull the upper half of the knee joint out of the thigh vinyl. You should be able to pull it out without tools.

If it won’t come out, heat it more. The vinyl will with stand more heating than you think. Just be careful not to touch the dryer to the vinyl to avoid burning it.

Continue the disassembly by pulling the thigh vinyl off of the hip joint. It should just slide off.

To remove the lower part of the broken knee joint, heat the shin just above the ankle.

Grasp the ball part of the ankle joint and pull the entire foot and ankle off. Again, heat, heat, heat!

With the foot off, use an unsharpened pencil or dowel rod or some other blunt object and push the lower knee joint peg up and out of the top of the shin.

If the peg doesn’t push out easily you may need to heat the top of the shin vinyl.

As you can see, the ends of the pegs next to the ball part of the joint are ribbed. This ribbing helps hold the skeleton parts in the vinyl but still allows the parts to rotate.

With the joint disassembled, now is the time to adjust the knee joint tension. I don’t recommend adjusting these joints except under extreme circumstances. These joints will seem very stiff, especially compared to elastic jointed resins, but tight joints are a good thing. Tight joints allow these dolls to really hold a pose. So I wouldn’t mess with these.

But now that we’re here, this is what you would do. This is also what you would do to tighten up a loose joint.

Pop one of the half domes of the ball joint off. This can be done by taking a hobby knife and easing the blade between the dome and the center disk of the joint.

If you’re lucky you’ll see a small Philips bolt head in the center. If you see a hex nut, the bolt head is on the other side so remove the other dome.

With a small Philips screw driver tighten or loosen the bolt head as needed, depending on if you’re tightening or loosening the joint. Replace the domes before installing the joint. The domes are the same on both sides and will just snap right in with the “slot” in the edge going towards the thigh.

Now you’re ready to place the new knee joint in the leg. First we’ll assemble the upper part of the leg.

Insert the upper peg into the bottom of the thigh vinyl. If you can’t push it in, heat the vinyl.

You should see the peg need the top opening of the thigh.

With one hand hold the knee joint and thigh vinyl so the peg is centered in the opening. Now try to inset the hip joint so the peg goes into the hip joint.

Next slip the bottom peg into the top of the shin vinyl. The two vinyls should fit nice and tight around the ball. If the shin doesn’t push on easily, heat ‘er up.

Finally you need to re attach the foot/ankle. Again, heat the bottom of the shin vinyl till it’s soft, then push the top of the ankle into the shin vinyl while trying to engage the peg. Once the peg has started into the ankle joint, push the ankle joint completely into the shin vinyl. The large collar at the bottom of the ankle tube needs to go into the shin vinyl. Heat the vinyl as needed.

That should do it.